charpy impact tester schematic|what is charpy impact test : wholesaling The Charpy impact test is performed to evaluate the resistance of the metal to breakage by flexural shock or impact load according to standard test method ASTM D6110. Fig 1: Charpy . WEBBest Online Slot Sites in 2024. 🎰 BetMGM - Best online slots site with the largest progressive jackpots. 🎰 Caesars - Excellent slots site for high-rollers. 🎰 FanDuel - User-friendly slots .

{plog:ftitle_list}

webCamisetas em promoção que você procura? Na Americanas você encontra as melhores ofertas de produtos com entrega rápida. Vem!

This page introduces the Charpy impact test principle and methods; as well as evaluation methods, test piece standards, differences from the Izod impact strength test, and methods for measurement of the fracture surface.The Charpy impact test is performed to evaluate the resistance of the metal to breakage by flexural shock or impact load according to standard test method ASTM D6110. Fig 1: Charpy .Identify and measure the initial lateral dimensions of all specimens. Conduct impact tests on 5 as received 1018-steel and five aluminum (2024 or 6061) specimens heated or cooled to dry ice, .The NIST Instrumented Charpy Analysis Software (NICAS) is a standalone LabVIEW1 program that can be used to analyze instrumented impact tests in accordance with the following .

Charpy impact testing is a low-cost and reliable test method for measuring the impact resistance of materials and is commonly required by construction codes for fracture- critical structures .

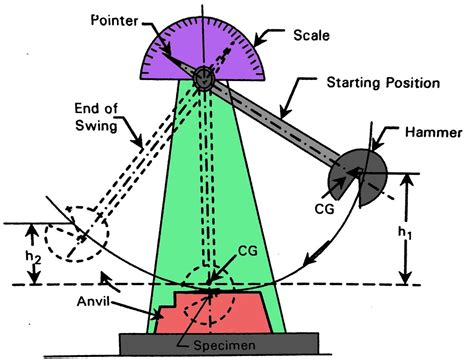

The Charpy V-notch impact is a mechanical test for determining qualitative results for material properties and performance which are useful in engineering design, analysis of structures, and .The Charpy impact tester consists of an impactor mounted at one end of a metal rod whose other end is anchored to a rigid frame at a pivot point; see Fig. 7.1. The impactor and the rod

The main objective of this study is to evaluate the results of Charpy impact test and QSPT on glass-fiber-reinforced epoxy nanocomposites. . Quasi-Static Penetration Behavior of Glass . The Charpy test involves striking a suitable test piece with a striker, mounted at the end of a pendulum. The test piece is fixed in place at both ends and the striker impacts the test piece immediately behind a a machined .

what is charpy impact test

Charpy impact testing is a(CIT) n ASTM standard fracture mechanics technique used to . Figure 2-2: A schematic of a Charpy impact test. 2. Some materials, upon cooling below a critical temperature, will exhibit a rapid decrease in their measured impact toughness. This change is called a ductile to brittle transition (DTBT).The Charpy impact test is carried out in a 3-point flexure setup.The Charpy specimen is centered on the supports in the pendulum impact tester and rests against two anvils. In the case of notched specimens, the notch faces away .Download scientific diagram | Schematic diagram of the Charpy impact tester and end-view of the composite sample configuration for impact tests. from publication: Polymer fibre composites .

Materials – Charpy Pendulum Impact Test – Part 1: Test Method,7 consists of a physical part (direct verification) and an experimental part (indirect verification). The direct verification consists in the detailed evaluation of . Schematic of a Charpy impact test. FIG. 2 Illustration of shear lips in Charpy (left) and tensile (right) tests.

The Charpy impact specimens of each material are immersed in a bath for 10 minu tes to reach thermal equilibrium at five separate temperatures ranging from 110oF (-79oC) to 212-oF (100oC). The specimens are quickly transferred to the Charpy testing machine, fractured, and the impact energy is measured. After

Charpy impact testing (also known as the Charpy v-notch test) is a high strain rate testing standard that determines the amount of energy absorbed by a material during a fault (Kim et al., 2015).Download scientific diagram | Schematic of a sub-size Charpy impact test specimen. from publication: Two Step Ductile to Brittle Transition Behavior on Ferrite + Pearlite Structure Steel Sheet .The three most popular types of tests for a single impact are Charpy V, Izod and tensile impact. These three tests determine essentially the same characteristics of the material, but differ in the orientation of the test specimen, which causes the specimen to strain in different directions and involves a known weight released from a known .Charpy Impact tester (Zwick HIT50P), as shown in Figure 4, was used. As the pendulum strikes with the composite sample, it exerts the impact of energy and breaks the sample. .

Understanding the critical importance of Charpy Impact Testing sets the stage for delving into its step-by-step procedure and intricacies – an insightful journey that demystifies this essential method for assessing material toughness. Step-by-step Procedure of a Charpy Impact Test. Performing a Charpy impact test involves several important steps.(ksi), and CVN is the standard Charpy V-Notch impact test value. 3 . Schematic Drawing of a Standard Impact-Testing Apparatus. [Callister, 1991] Background - Statistical Considerations Chauvenet's Criterion Engineers often find that some data points look bad and out of place in comparison with the bulk of the data in a set of repeated .Download scientific diagram | Figure . Schematic of the instrumented Charpy impact test. from publication: An Experimental and Numerical Study of the Dynamic Response of Composites under Impact at .The Charpy impact test uses a standard Charpy impact machine to evaluate this impact energy. The machine consists of a rigid specimen holder and a swinging pendulum . Figure 3 Schematic of plot of impact energy versus temperature showing sigmoidal curve. LABORATORY REPORT 1. Include the following information in the laboratory report.

Figure 3 showed sample for Charpy V-notch test prepared as per ASTM E23-12c standard22.The hardness measurements were taken using Brinell hardness tester23 (make-: MIRAJ, INDIA, Model:3000(O) of .Download scientific diagram | Schematic illustration of Charpy Impact Testing from publication: Impact Test Analysis on Steel Metal Materials and Aluminum | Impact testing is carried out to . The Charpy impact test is used to characterize toughness; the NIST Charpy program both produces and certifies specimens for use with impact test machines, and works directly with over 1,500 test labs per year to diagnose problems that may arise during verification testing. . Schematic of an instrumented Charpy test. Instrumented Charpy .Download scientific diagram | Schematic diagram of charpy impact test's specimen. from publication: Study on the weldability, microstructure and mechanical properties of thick Inconel 617 plate .

The schematic illustration of the Charpy impact test and test machine is shown in Figure 6 a and b, respectively. Where í µí± is the absorbed energy(J), í µí°ís the area (m 2 ), and í .

The Charpy impact test has been used worldwide since the late 1800s/ early 1900s [3,4] for characterizing the notch toughness of metals, and thereby their suitability for applications ranging from ship hulls and railroad tracks to nuclear reactor pressure vessels.

The Charpy impact test was invented in 1900 by Georges Augustin Albert Charpy (1865–1945), and it is regarded as one of the most commonly used test to evaluate the relative toughness of a material in a fast and economic way. The Charpy impact test measures the energy absorbed by a standard notched specimen while breaking under an impact load. This test continues to be .Charpy Impact testing is used in studying material toughness and most importantly it indicates a material ability to absorb energy and plastically deform without fracturing. In this study, three stainless steel specimens at different temperature -78°C, 80°C and 7°C respectively were utilized. They were one at a time properly placed within a .Schematic of a Typical Charpy Impact Testing Machine. In carrying out a test, the specimen is loaded into the anvil with a pair of special tongs that facilitate location of the specimen in the machine. The specimen is supported at each end as shown in Figure 2 and the pendulum strikes the back of the specimen behind the notch. This puts the .

The Charpy impact test (Charpy V-notch test) is used to measure the toughness of materials under impact load at different temperatures! Test setup and test procedure. In the Charpy impact test, a notched specimen is abruptly subjected to bending stress. The specimen is usually 55 mm long and has a square cross-section with an edge length of 10 mm.In this study, the Charpy impact test was conducted using an impact test machine-Impact Tester MT3016, Wolpert. The geometry and dimension of impact specimen is illustrated in Fig. 1.

Figure 1 shows a schematic drawing of the instrumented Charpy V-notch impact test set-up, which consists of the specimen, the anvils, the striker equipped with wire resistance strain gauges, the .The basic principle and practical procedure of the Charpy impact test on Different Metal* Apparatus used for test- Testing machine, The test specimen, Scale*.The impact energy needed to fracture an unnotched Charpy specimen in a BFCM test can be two orders of magnitude higher than the typical impact energy of a Charpy V-notch specimen.

testo 320 basic flue gas analyzer

what is flue gas analyzer

Resultado da 17 de jan. de 2024 · Football, basketball, and wrestling are among the sports you can bet on at ZenBet. Here's a review analyzing more about ZenBet.

charpy impact tester schematic|what is charpy impact test